Founded in 1865 in the mill acquired by Thomas Arkell 1827.

Still brewing in 2012 with 15 public houses.

See ‘A Brewery in the Countryside‘.

I am grateful to Paul Best for the following information on Donnington Brewery.

1841 census John Arkell.

Dwelling; Street, Stratton St Margaret, Wilts.

John Arkell. Age 35. Farmer. Born; Out of County.

Elizabeth Arkell. Age 25. Born; Out of County.

Thomas Arkell. Age 7. Born; In County.

William Arkell. Age 5. Born; In County.

Elizabeth Arkell Age 3. Born; In County.

John Arkell. Age 1. Born; In County.

Daniel Arkell. Age 3 months. Born; In County.

Elizabeth Scott. Servant. Age 15. Servant. Born; Out of County.

Elizabeth Browning. Servant. Age 15. Servant. Born; Out of County.

Elizabeth Hind. Servant. Age 20. Born; Out of County.

Elizabeth Hewer. Age 60. Independent Assets. Born; Out of County.

Jonathan Loveday. Servant. Age 20. Born; In County.

Rich Pool. Servant. Age 15. Servant. Born; Out of County.

Thomas Trinder. Servant. Age 15. Bourn; Out of County.

1851 census John Arkell.

Dwelling; Kingsdown Inn, Stratton St Margaret, Wilts.

John Arkell. Head. Age 43. Brewer and Inn Keeper. Born; Kempsford.

E. Arkell. Wife. Age 35. Born; Kempsford.

T. Arkell. Son. Age 16. Brewer. Born; Stratton, Wilts.

J. Arkell. Son. Age 11. Scholar. Born; Stratton, Wilts.

S. Arkell. Daughter. Age 8. Scholar Born; Stratton, Wilts.

H. Arkell. Son. Age 5. Scholar. Born; Stratton, Wilts.

R. J. Arkell. Son. Age 3. Born; Stratton, Wilts.

A. H. Arkell. Daughter. Age 2. Born; Stratton, Wilts.

J. Arkell. Son. Age 5 months. Born; Stratton, Wilts.

Elizabeth Hewer. Mother in Law. Age 71. Landowner. Born; Berkshire.

Ann Baden. Visitor. Age 22. Born; Charlton, Wilts.

Ann Reynolds. Servant. Age 17. Housemaid. Born; Hannington, Wilts.

Ann Titcombe. Servant. Age 15. Nursemaid. Born; Stanton? Wilts.

James Dodd. Lodger. Age 75. Drover. Born; Highworth, Wilts.

Richard Gearing. Lodger. Age 19. Drover. Born; Lechlade, Glos.

1861 census Richard Iles Arkell.

Dwelling; Boarding School, Faringdon.

Richard Illes Arkell. Boarder. Age 13. Scholar. Born; Kingsdown, Swindon, Wilts.

1871 census Richard Arkell.

Dwelling; Donnington, Glos.

Richard Arkell. Head. Age 23. Brewery Manager. Born; Stratton St Margaret, Wilts.

Elizabeth Knight. Servant. Age 55. House Keeper. Born; Wiltshire.

Ellen Bradford. Servant. Age 12. General Servant. Warwickshire.

1881 census Richard Arkell.

Dwelling; Donnington. Glos.

Richard Arkell. Head. Age 34. Brewer & Maltster. Born; Stratton St Margaret, Wilts.

Mary Arkell. Wife. Age 31. Born; Longborough, Glos.

Richard Arkell. Son. Age 5. Born; Donnington, Glos.

James Arkell. Son. Age 2. Born; Donnington, Glos.

Herbert Arkell. Son. Age 1. Born; Donnington, Glos.

Fanny Edgeworth. Servant. Age 18. General Servant. Born; Oddington, Glos.

Jane Preston. Servant. Age 13. Nursemaid. Born; Condicote, Glos.

1891 census Richard Iles Arkell.

Dwelling; Donnington Brewery.

Richard Illes Arkell. Head. Age 43. Brewer. Born Stratton St Margaret, Swindon.

Mary Arkell. Wife. Age 41.

Richard S. Arkell. Son. Age 15. Scholar. Born; Donnington Mill, Glos.

Dennis J. Arkell. Son Age 12. Scholar. Born; Donnington Hill, Glos.

Susan E. Arkell, Daughter. Age 9. Scholar. Born; Donnington Mill, Glos.

Algernon H. Arkell. Son. Age 6. Born; Donnington, Glos.

Elizabeth A. Collier. Servant. Age 25. General Domestic Servant. Born; Bourton Hill, Glos.

Elizabeth G. Statter, Servant. Age 16. General Domestic Servant. Born; Campden, Glos.

1901 census Richard Iles Arkell.

Dwelling; Donnington Brewery

Richard Iles Arkell. Head. Age 54. Brewer & Famer. Employer. Born; Stratton St Margaret, Wilts.

Mary Arkell. Wife. Age 52. Born; Longborough, Glos.

Richard S. Arkell. Son. Age 25. Farmers Son Assistant. Worker. Born; Donnington, Glos.

Herbert J. Arkell. Son. Age 21.Farmers Son Assistant. Worker. Born; Donnington, Glos.

Susan E. Arkell. Daughter. Age 19. Born; Donnington, Glos.

Edith A. Colderott. Servant. Age 15. Housemaid Domestic. Born; Lower Slaughter, Glos.

1911 census Richard Iles Arkell.

Dwelling; Duncombe House, Stow On The Wold, Glos.

Richard Iles Arkell. Head. Age 63. Brewer & Famer. Employer. Born; Kingsdown Swindon, Wilts.

Mary Arkell. Wife. Age 61. Born; Longborough, Glos.

Susan Elizabeth Arkell. Daughter. Born; Donnington Mill, Glos.

Emily Muriel Batts. Servant. Age 17. Domestic Servant. Born; Turkdean, Northleach Glos.

Florence Kate Hyde. Servant. Age 16. Domestic Servant. Born; Lower Swell, Glos.

1919 Probate Richard Iles Arkell.

Of Duncombe, Donnington Gloucestershire, brewer died 11th April 1919. Probate Gloucester 2nd March to Richard Sidney Arkell farmer and Dennis James Arkell and Herbert John Arkell, brewers.

Effects £45095 17s. 8.

Source; National Probate Calendar.

Tied Houses

Bell Inn, Gretton Road, Winchcombe (1891,1903)

Black Bear, Moreton in Marsh (1891,1903)

Coach & Horses, Ganborough (1891,1903)

Coach & Horses, Longborough (1891,1903)

Dog and Gun, Chandos Street, Winchcombe (1903)

Farmers Arms, Guiting Power (1903)

Fox Inn, Lower Swell (leased 1891)

Golden Ball, Lower Swell (leased 1903)

Kings Arms, Chipping Campden (1891)

New Inn, Willersey (1891,1903)

Queens Head, Market Square, Stow on the Wold (1891,1903)

Swan Inn, Chipping Campden (1891,1903)

A Brewery in the Countryside

By H. Hurlbutt Albino

Extracted from the ‘Gloucestershire Countryside’ Volume 5. No. 6.

Published 1944-1945

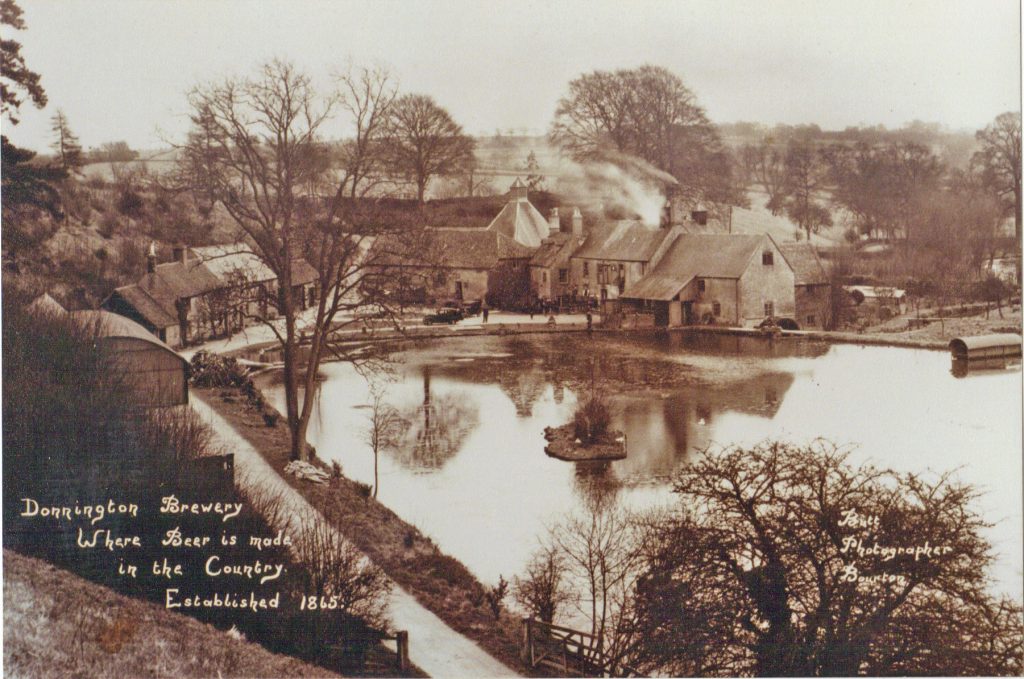

In a quiet Cotswold valley, secluded and away from any village, its slopes patterned with cornfields and pastures and clumps of trees, the whole forming a frame to a sheer of water, lie a group of buildings. They are attractive to the eye in their setting and many different shapes. Birds and animals are conspicuous in the way they grace the scene: like the pigeons which bask in the sun in their holes on the side of the building, and the grazing horse on the hill slope; the water fowl, and the ducks and geese, alternately seeking food on the grass and then taking to the water; and the gold fish which ornament a patch of water by the bank – a happy blend of wild and tame life. Coming on to a scene hidden in such peace and calm, as if avoiding all contact with the outside world, is a little surprising after descending a steep lane to see a chimney belching black smoke and steam rising from large ventilators until the breeze wafts before one the unmistakable aroma of malt and the pungent smell of hops gives the clue as to what is going on – smells common enough in town but almost unique in the country these days.

Originally a water mill, these buildings were adapted to the use of a brewery some eighty or more years ago. The lake, which is really the mill-pound and one of the largest in the district, is still used for turning the wheel, which now works the pumping machinery rather than the mill stones, as no steam engine is used. A glance inside the main building shows how stout posts and massive beams have been inserted to take the extra weight of the brewing plant above. Much ingenuity must have been used to transform a mill into a brewery with all its subsidiary rooms, like the office, the excise room, the hop room, and the heavy plant placed near the roof.

Inside, a feeling of quiet, steady industry is at once noticeable. There is the continual rumble of the machinery down below pumping up water from the spring; occasionally a figure goes up or comes down the stairs rather mysteriously, for the human element is seemingly so scarce. He may be the brewer, who at a stated time must go up to the hop room to weigh out the portion of hops for the day’s brewing, carry them in a sack up a difficult flight of steps and tip them into the boiling copper. Sounds from below may mean barrels being washed and damaged ones sorted out to be sent to the cooper. Later in the day there are more signs of activity. The mash is shovelled out of the mash tun into a bin to be taken away for pig food and the tun washed scrupulously clean. A very watchful eye is kept on the thermometer showing the temperature of the liquid as it runs down the cooler into the fermenting tun.

The hauling-up of the filled barrels from the dark cavernous cellar to the ground floor is a strange and almost eerie experience to watch. Attaching the rope to a barrel, the brewer gives a queer, distant little call in his throat as a signal for the two men above to start winding up, using a very crooked stick for steadying the cask from the tendency to spin and so be kept straight for going through the doors in the floor. When right through, the winders let it down with a thud, detach it from the rope and roll it out of the way, its great weight producing a rather alarming vibration on the floor. After many barrels of various sizes have been hauled up they are loaded onto the lorry and delivered to the inns in the district which belong to the brewery – for it has its own number of ‘tied’ houses in nearby villages.

At the other end of the buildings are the malt house and kiln with the residential house sandwiched in between. Opposite are stables, cart sheds, a cottage or two, a forge and a wheelwright and carpenter’s shop. For this brewery is a very complete and almost self-contained little community. Belonging to and surrounded by it is a mixed farm of over four hundred acres which grows the barley. Besides repairs to farming tackle, the carpenter attends to the wooden parts of the brewery machinery, while the smith sees to the iron work. This is a unique example, rare these days, of all processes of an industry being kept under one head. We have a farm producing not only the barley for the malt but also the usual crops and stock, with the craftsmen necessary for both brewery and farm working on the premises in closest contact with the master.

As possibly the different processes in brewing are not generally known it may be of interest to describe them very simply.

Malt is produced by barley being steeped in water for some two days or more. After it has remained in the steep for sufficient time the water is drained off and the barley thrown out of the tank onto the floor and formed into a heap, called a couch, about sixteen inches deep and left in this position for some twenty four hours or more. It is then turned over by wooden shovels and diminished a little in depth. This turning is repeated twice a day or more and the grain spread thinner and thinner till at last it is only a few inches deep. When placed in a couch the grain gradually increases in temperature and becomes moist again. It is now that it gives off the well-known agreeable odour. The roots of the grain begin to appear and also the rudiments of the future stem. This produces a change in kernel of the grain, which is the object of mashing. The process is now stopped by drying the malt on the kiln with the heat being gradually increased. The malt is now crushed and mixed in a mash tun with hot water and allowed to stand for a time, the resulting liquid being called sweet wort. It is then pumped into the copper for boiling when the hops are put in.

Hops, besides giving the bitter flavour, act as a preservative. After boiling it is run into the hop-back, a tank for separating the hops. As the boiled worts drain from the hops they run, at this particular brewery, into a wooden shallow, tray-like tank for a first cooling off and then down a cooling plant into the fermenting tun. It is most important that the right temperature be reached for fermenting. When the tun is about a quarter full a pail, shining like silver and full of barm looking rather like cream, is tipped in and the tun allowed to fill up. When the fermentation has come to a certain point the yeasty head is skimmed off the top. This is done several times until the beer is clear, when it is racked into casks or a tank for bottling. The barm is used for a number of times and then exchanged with another brewery to get new life – “to keep up the breed.”

Cleanliness is of great importance and all vessels and barrels have to be scrubbed with boiling water each time before using. Much labour and toil go to the making of the national beverage – in this case all is done with five pairs of hands, and holiday times are the busiest.

Then there is the excise officer. Any moment of the day or night he may enter for his purpose of testing and inspection. The law allows him to have the key of the brewery for that purpose. Brewing is the most highly controlled of any industry.

Tacitus tells us that the brewing of beer was known in very remote ages in the northern countries. After the introduction of agriculture into this country malt liquors were submitted for those made from mead and became the general drink of the Ancient Britons.

“We just brew beer in the old-fashioned way,” says one of the hands, while scrubbing the inside of a vat, whose father and grandfather worked in the same brewery. Which means they use malt and hops and nothing else. And certainly their excellent beer tastes so.