Founded 1760 as Watts, Hallewell & Co. Registered 1888. 643 tied houses. Merged with Cheltenham & Hereford Breweries Ltd. In 1958 to form West Country Breweries. Used as a Whitbread depot until 1969 and was demolished in 1970.

Tied houses 1891 and 1903

Admiral Benbow, 78 Westgate Street, Gloucester

Amberley Inn, Amberley (1903)

Anchor Inn, 44 Sweetbriar Street, Gloucester

Apple Tree, Coombe Road, Wotton under Edge (1891)

Avenue Hotel, Bristol Road, Gloucester

Bear Inn, George Street, Bisley (1891,1903)

Bedford Arms, 51 High Street, Stroud (1891,1903)

Bell and Castle, Parsonage Street, Dursley (1903 lessee)

Bell and Castle, The Cross, Horsley (1903)

Bell Inn, Bisley (1903)

Bell Inn, Wallbridge, Stroud (1891,1903)

Berkeley Arms, Cam (1891,1903)

Bisley House, 47 Middle Street, Stroud (1903)

Black Dog, London Road, Gloucester

Black Horse, Amberley (1903)

Black Horse, Gillingstool, Thornbury (1903)

Black Horse, Tilputs End, Horsley (1891,1903)

Box Inn, Box (1903)

Brewers Arms, Coombe Road, Culverhay, Wotton under Edge (1903)

Bricklayers Arms, Stroud

Bridge Inn, Dudbridge (1891,1903)

British Oak, London Road, Bowbridge, Stroud (1891,1903)

Butchers Arms, Ampney Crucis (1903)

Butchers Arms, Acre Street, Stroud (1891,1903)

Canal Tavern, Bowbridge (1891,1903)

Clothiers Arms, Bath Road, Rodborough (1891,1903)

Companys Arms, Chalford (1891,1903)

Coach and Horses, Westward Road, Ebley (1903)

Coopers Arms, Stroud (1891,1903)

Cross, Avening (1891,1903)

Cross Hands, 2 Summer Street, Stroud (1891,1903)

Cross Keys, High Street, Bream, Lydney

Crown and Anchor, High Street, Stonehouse (1891,1903)

Crown and Sceptre, Horns Road, Stroud (1891,1903)

Crown Hotel, Station Road/Clarence Street, Gloucester

Crown, Long Street, Dursley (1891,1903)

Crown, Cockshut Hill, Kingswood (1891,1903)

Crown, Nailsworth

Crown, Inchbrook, Nailsworth (1891,1903)

Crown, Sheepscombe (1891,1903)

Dial Inn, St. Marys Square, Gloucester

Drovers Arms, Bristol Road, Coaley (1891,1903)

Duke of York, Chalford Hill (1891 lessee, 1903)

Eagle, Pitchcombe (1891 lessee, 1903)

Falcon Hotel, New Street, Painswick (1891,1903)

Fleece, Bisley Street, Painswick (1891,1903)

Fleece, Lightpill, Rodborough (1891,1903)

Foresters Arms, Claypits, Thrupp 1891, 1903 lessee)

Fountain, 27 Slad Road, Uplands, Stroud

Fox and Hounds, Hill Road, Dursley

George, Cambridge

George, Newmarket, Nailsworth (1891,1903)

George, Yorkley (1891,1903)

Globe, Lower Leazes, Stroud (1891,1903)

Golden Cross, Avening

Golden Heart, Tibiwell, Painswick (1891,1903)

Greyhound, Popes Hill, Drybrook (1903)

Half Moon, Hill Street, Stroud (1891,1903)

Haywardsfield Inn, Ryeford, Stonehouse (1891 lessee, 1903)

Hope and Anchor, Uplands, Stroud (1891,1903)

Horse and Farrier, Avening (1891)

Horse and Groom, Upper Leazes, Stroud (1891,1903)

Jovial Forester, Northfield Road, Forest Green, Nailsworth (1903)

Junction Inn, Saul (1891,1903)

Kings Arms, Bourne Lane, Brimscombe (1891,1903)

Kings Arms, Wallbridge, Stroud (1903)

Kings Head, 295 High Street, Cheltenham (1891,1903)

Kings Head, Forwood, Minchinhampton (1903)

Kings Head, Market Street, Nailsworth (1891,1903)

Kings Head, 41 High Street, Stroud (1891,1903)

Kings Head, Kingscourt, Rodborough (1891,1903)

Lamb, Butterow, Rodborough (1891,1903)

Lamb, Church Street, Stroud (1891 lessee)

Leopard, Parliament Street, Stroud (1891,1903)

Llanthony Bridge Inn, Llanthony Road, Gloucester

Lower Crown, Uley (1891,1903)

Marlborough Arms, Sheep Street, Cirencester (1891,1903)

Merryfellow, Church Street, Charlton Kings, Cheltenham

Mitre Inn, Wortley Road, Wotton under Edge (1903 lessee)

Nags Head, Kings Stanley (1903 lessee)

New Inn, 40 Lower Street, Stroud (1891,1903)

New Inn, Kingswood, Wotton under Edge (1903)

New Inn, Viney Hill, Lydney (1891,1903)

New Inn, Whitecroft, Lydney (1891,1903)

Old Crown, Chapel Lane, Ebley (1891,1903)

Old Crown, St. Briavels (1903)

Old Fleece, Ronksmoor, Rodborough (1891,1903)

Old Red Lion, Chalford (1903)

Orange Tree, Hill Street, Stroud (1891,1903)

Pear Tree, Charfield (1903)

Pheonix, Thrupp (1891,1903)

Plough, Minchinhampton (1891,1903)

Plough, Stratton, Cirencester (1891 lessee, 1903)

Plough, Union Street, Stroud (1891,1903)

Post Office Inn, 17 George Street, Stroud

Prince Albert, Rodborough Hill (1891,1903)

Princess Royal, Butterow, Rodborough (1891,1903)

Queens Head, Longford, Gloucester (1891,1903)

Railway Hotel, Ambrose Street, Cheltenham (1891,1903)

Railway Hotel, Russell Street, Stroud (1891 lessee,1903)

Railway, 97 Tewkesbury Road, Cheltenham

Railway, Dudbridge Road, Rodborough

Railway Tavern, St. Mary’s Way, Brownshill, Chalford (1903)

Ram, Market Place, Minchinhampton (1903)

Ram, Station Road, South Woodchester (1891,1903)

Red Lion, Eastcombe (1891,1903)

Red Lion, Market Street, Nailsworth (1903)

Rising Sun, Shortwood, Nailsworth (1903)

Rising Sun, Randwick

Rising Sun, Nelson Street, Stroud (1891)

Rose, Paganhill (1891,1903)

Royal Arms, Burdett Road, Stonehouse (1891 lessee, 1903)

Royal Oak, Well Lane, Minchinhampton (1903)

Royal Standard, Swindon Road, Cheltenham (1891 lessee)

Salutation, Tetbury Street, Minchinhampton (1891,1903)

Sawyers Arms, Avening (1903)

Shearmans Arms, The Steep, Wotton under Edge (1891,1903)

Shears, Watledge, Nailsworth 1903)

Ship, Brimscombe (1891,1903)

Ship, Framilode (1891,1903)

Ship, High Street, Newnham on Severn (1891,1903)

Ship, Bristol Road, Stonehouse (1891,1903)

Ship, Wallbridge (1891)

Spread Eagle, Harescombe (1891,1903)

Spread Eagle, Newport (1891)

Spring Inn, Cainscross (1891,1903)

Star, Silver Street, Dursley (1891,1903)

Star, Kings Stanley (1891,1903)

Star, Forest Green, Nailsworth (1891,1903)

Star, Buddings, Slad (1891,1903)

Star, Tower Hill, Stroud (1891,1903)

Star, Market Place, Wotton under Edge (1891 lessee)

Sudeley Arms, Winchcombe Street, Cheltenham (1891 lessee)

Swan, George Street, Stroud (1903)

Ten Bells, Frogmarsh, Woodchester (1891 lessee, 1903 lessee)

Trout, St. Johns Street, Lechlade (1891 lessee)

True Heart, Newnham on Severn (1891,1903)

Trumpet, West End, Minchinhampton (1903)

Tump House, New Road, Blakeney (1903)

Victoria Tap, Stroud (1891,1903)

Vine Tree, Randwick (1891,1903)

Waggon and Horses, London Road, Thrupp (1903)

Washington Head, Bradley Street, Wotton under Edge (1891,1903)

Weavers Arms, Middleyard, Kings Stanley (1891,1903)

Weighbridge, Iron Mills, Longford (1903 lessee)

Wheatsheaf, Chalford Hill (1891,1903)

Wheatsheaf, Chapel Street, Thornbury (1903)

White Hart, Bisley (1891lessee)

White Hart, High Street, Minchinhampton (1891 lessee, 1903 lessee)

White Hart, Broad Oak, Newnham on Severn (1891,1903)

White Hart, North Nibley (1891 lessee, 1903 lessee

White Horse, Westwood Road, Cainscross (1891,1903)

White Horse, Downend, Horsley (1903)

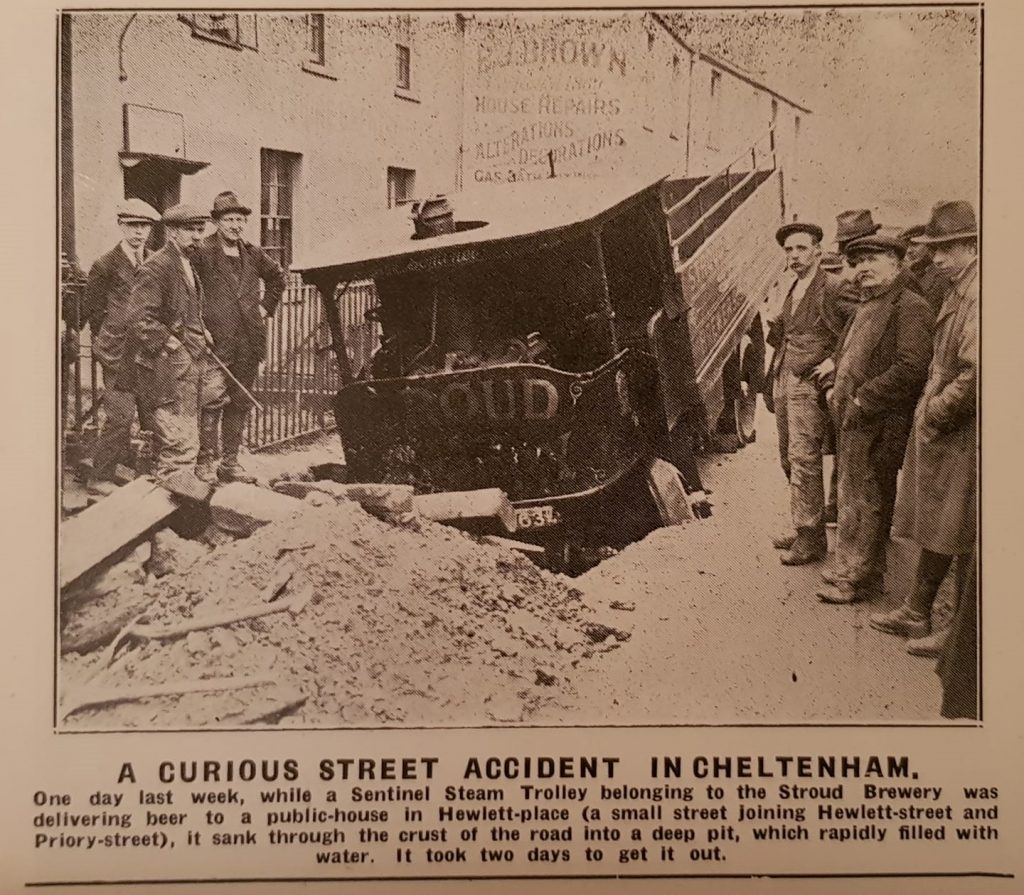

Wiltshire Brewery, Hewlett Place, Cheltenham (1903)

Woodcutters Arms, Whiteshill (1891,1903)

Woolpack, Butterow (1891,1903)

Woolpack, Slad (1903)

Ye Old Painswick Inn, 17 Gloucester Street, Stroud (1891,1903)

Ye Old Robin Hood Inn, Hopewell Street, Gloucester

Yew Tree, Walls Quarry, Brimscombe (1891,1903)

Yew Tree, Woodchester (1891,1903)

Stroud Brewery Co.Ltd

Peter Leversage of Middle Lypiatt, with his associates Mr Grazebrook and Mr Burgh, established the Stroud Brewery in about the year 1760. Peter Leversage was a farmer. After the retirement of Messrs Grazebrook and Burgh Mr Leversage took Mr Joseph Watts into the business and for 14 years traded under the name of Leversage & Watts. Joseph Watts took on a managerial role during this time and was a very successful businessman. In 1819 he became sole proprietor and ably conducted the business for a further 36 years. Joseph Watts was a philanthropist and was ever ready to devote his ability and his resources to any measure or undertaking which involved the betterment of Stroud and the welfare of its inhabitants. During the middle years of the 19th century no public man in Stroud earned a higher degree of general respect or conferred more benefit on the town and its inhabitants, that the chief founder of the Stroud Brewery. Joseph Watts died, aged 84, at Stratford House on October 17th 1855 and bequeathed the Stroud Brewery and Estate to one of his grandsons – Joseph Watts Hallewell. The brewery was then carried on by the partnership firm of Messrs. Watts Hallewell, Biddell and Stanton.

Teddy Wilkins was a well-known character in Stroud about 1800. He was a beer aficionado who conveyed his passion for the products of the Stroud Brewery through poetry. He composed a lengthy, if not particular poetic piece of prose – consisting of 84 stanzas, which began:

“When going, one day, to my employ,

I met a wagon load of joy :-

It made me thirsty to see’t – for why?

It came from Watt’s Brewery.”

The aspiring but delusional poet regarded his poem on the Stroud Brewery as his greatest work although it failed to gain any recognition. Teddy Wilkins died at Rodborough in 1825, from the effects of hard drinking.

Managing Directors and Chairmen of the Stroud Brewery Company.

1888 Mr J.Watts-Hallewell (Chairman)

1888 Mr James Stanton with Messrs. Sidney Biddell, Edmund Broderip and Colonel James A. Collier (Directors)

1892 Mr Hall-Bishop (Managing Director)

1891-1897 James Stanton (Chairman)

1897 Edward Playne (vacant seat on the Directorate)

1904-1907 Edward Playne (Managing Director)

1907-1928 Mr Maynard Willoughby Colchester-Wemyss (Managing Director and Chairman)

1928-1931 Hamilton Mills (Chairman)

1931-1940 Ernest Armitage (Chairman)

1944-1946 Sir John H. Percival, K.B.E., J.P. (Chairman)

1946 Lt. Colonel Kenneth B. Godsell, D.S.O., M.C (Chairman)

Mr Ernest Armitage became Chairman of the Stroud Brewery Co.Ltd. in 1931, following the retirement of Mr Hamilton Mills. He was chairman 1931-1940. Mr Armitage was farmer for over 45 years and his experience was gained when he was brought up on one of the best barley growing farms in Herefordshire.

Sir John H. Percival, K.B.E., J.P., who joined the Board on the 1st January, 1932 on the retirement of Mr. Hamilton Mills, was elected Chairman on the death of Mr A.W. Stanton in 1944, and he relinquished the Chairmanship at the end of June 1946.

Lt. Colonel Kenneth B. Godsell, D.S.O., M.C., was elected as Chairman to succeed Sir John Percival, carried on a successful brewing business for many years and, when their business was acquired in 1928, Major Godsell (as he then was) joined the Board of the Stroud Brewery Company, Ltd. Colonel Godsell was gazetted to the Royal Engineers in 1913, served with distinction in World War One, was mentioned four times in dispatches and was awarded the D.S.O. and M.C. He was recalled in 1939 and after service abroad, did valuable work in this country in bomb disposal and clearance of mine fields. He was also a keen cricketer and once achieved the remarkable bowling figures of 6 wickets for five runs in 1930.

Stroud Brewery: Key dates

1858: March, 23rd – ‘Hallewell & Biddell’s malt house at the brewery fell in and killed a man’. (Stroud news)

On June 5th 1896 the clerk of Stroud Urban District Council received a letter from a disgruntled visitor to the town who had observed that the chimneyof the Stroud Brewery Co. was “sending forth black smoke for more than five minutes” and constituted a nuisance.

27th January 1905. Stroud News. Stroud Brewery; ‘.. the Chairman then said that it was his pleasing duty to propose a vote of thanks to the staff of the brewery. Mr Playne had said that everything was working extremely satisfactory, and he (the Chairman) was certain that it would be impossible to have a better set of officials than those at Stroud Brewery.’ He added: ‘their brewer had accomplished that which very few other brewers were able to do, and that was to reduce the returns of beer to an absolute minimum. That was a feature which distinguished the Stroud Brewery somewhat pre-eminently among other breweries. He hoped the shareholders would sample the products of the Brewery, as he felt sure that they would be highly delighted with them. (Hear Hear).

24th December 1905: Advertisement in ‘Gloucestershire Echo’: ‘The Stroud Brewery Company Ltd. Est. 1760. ‘Brewers of Sparkling Ales and Nourishing Stout, especially adapted for household consumption, are now supplying from their branch stores, Warwick Place, Winchcombe Street, Cheltenham. Mild & Bitter Ales from 1/- per gallon, and Stout from 1/2d per gallon in four and a half casks and upwards. Also in bottle in perfect condition at current prices. Full Price List and Particulars on application to Harry Dredge, Branch Manager. A trial order is solicited.’

July 1907. The Stroud Brewery Co., Ltd.- Advert in ‘Stroud & Neighbourhood’: The Brewery with its high chimney, which forms a prominent landmark, stands at the lower entrance to the town, and is fronted by the magnificent suite of offices, including a fine board room, built in stone, in picturesque Cotswold style and covered with grey stone tiles, the whole presenting an imposing and distinctly pleasing appearance. Some twelve years ago the Brewery itself was re-modelled and fitted with entirely new plant, and is today fully equipped with every modern appliance, no expense or trouble being spared in that respect. The water for brewing,which is of the finest and purest, is obtained from the far-famed Callowell Springs and from Gainey’s Well, brought by pipes direct into the Brewery, whilst for cooling and washing purposes, water at a very low temperature only varying one degree between Winter and Summer, is derived from two deep artesian bored wells on the Brewery premises, each giving 3,000 gallons per hour. The whole of the malt required for brewing is made in the Company’s malthouses (of which there are three) attached to the Brewery, great care being taken in this department to ensure the production of first-class malts from which to brew the finest quality beers and stout, for which this Company is so justly celebrated throughout the West of England. It is interesting to note that large quantities of the barleys are purchased from the farmers locally. New Casks are also made on the premises.

January 1908 – ‘Mr W.W. Colchester-Weymss, Chairman and Managing Director, presided at the Stroud Brewery Annual Meeting. The Chairman paid a tribute to the late Mr. Edward Playne, their Managing Director. ‘They had had a successful year and in some particulars slightly better than the preceding year. The barley crop had not been so favourable, and they had been obliged to buy foreign barley. Hops were cheaper, but not as good as when prices were higher.’

1910 – The Company purchased its first lorry from Messrs. James Hall of Dartford. The lorry was a ‘Halford’, chain driven with solid tyres, two paraffin side lights and one acetylene head lamp. With the 1914 War lorries and Drivers were on the Reserve, and in August 1914 three of the Company’s vehicles were sent to France. At the wheels were Messrs. Bill Stafford, George Taylor and Archie Marsh. Demobbed in 1918 Bill returned from German East Africa to the Transport Dept to take over a ‘Peerless’ lorry.

1910 – 17th June. Stroud News: Sugar In Beer – “in replying to a question as to what beer was made of and whether sugar should be used in its manufacture, Mr Colchester-Wemyss explained that only in about one harvest in ten or twenty did English barley contain to the full the peculiar virtue given to it by the sun, which was present in foreign barleys, and therefore the addition of a little sugar was necessary to make up for this deficiency. It was quite possible to brew beer from foreign barley without the addition of sugar but when made from English barley or a mixture of foreign and English the taste in beer had so changed that the brewers had found it necessary in order to suit the palate of the public that a certain amount of sugar must be used. When it was remembered that English barley was in direct competition with foreign it would be recognised that the use of sugar was distinctly beneficial to English farmers and in no way detrimental to them.”

1913 – 5th September. ‘Stroud News’: N.&W. Cook, Tetbury Brewery – Acquisition by the Stroud Brewery Company: “This Company with its well-known enterprise has, we are pleased to announce, made arrangements to purchase the old established and well-known brewery of Messrs N.&W. Cook at Tetbury together with all their licensed houses, mostly situated in Gloucestershire and Wiltshire, and of which they will obtain possession on the 30th September 1913. This purchase, which is an extensive one, should considerably enhance the Company’s position. Brewing operations will be continued at Tetbury for some months pending alterations being carried out to the Company’s brewery at Stroud, which is now one of the most modern fitted in the county and from whence their well-known and highly popular products are sent into and the surrounding counties (sic). It may be interesting to recall that during last year the same Company purchased the Malmesbury Brewery and licensed houses belonging to Col. Luce, and that the purchase has, as far as we can learn, proved a very successful one.” 33 public houses were included in the purchase.

1925 Shareholders Meeting – ‘operations of the [Stroud Brewery] Company now extend into no fewer than five counties; namely a large proportion of Gloucestershire and Wiltshire, and a certain portion of Oxfordshire, Herefordshire and Monmouthshire. A few years ago that sort of business would have been impossible from Stroud, but it had now been made possible by the advent of motor lorries, and in this connection, they have a very handsome fleet of lorries.’

1925 Shareholders Meeting: ‘There was one interesting little fact in connection with the trade, and that was there was a tendency all over the country for people to show an increasing preference for bottled beer, sales in this connection having increased very considerably, There was a tendency for people to prefer bottled beer otherwise than naturally conditioned. In view of this the directors had just concluded arrangements for the installation of a complete chilling and carbonating plant which was necessary for modern requirements, and this would be in full working order sometime in the new year.

1926 Shareholders Meeting (3rd December): ‘their chief item of expenditure, however, had been in connection with the development of their bottled beer department. Previously the beer was bottled and kept until it was matured, but now it was chilled and aerated by a special process. the sales of bottled beer had increased very largely, and the advantage of the new plant which had been installed was that directly it was bottled it was fit to drink, being brilliant in colour, and could be drunk to the last drop.

1928 – October 27th: The Head Brewer of Stroud Brewery, Mr J.D. Wilson, died in a motoring accident in London Road, Stroud. By an irony of fate, a motor lorry belonging to the Stroud Brewery Company skidded and passed over him.

1931- Cheaper Ale. The Stroud Brewery Co., Ltd., will supply a special ale for the Haymaking and Harvest Seasons, 1931, known as ‘H.A. at the following prices: Pin – £0.7s.6d. Firkin – £0.15s.0d. Kilderkin – £1.10s.0d. Barrel £3.0s.0d. Hogshead £4.10s.0d. Less usual discount for cash 1 month. Prompt Delivery. The Brewery, Stroud. ‘Phone No.463 (2 lines).

June 1945 – First edition of the Stroud Brewery Courier edited by Archie Ralph Selby.

March 1947: The seriousness of the fuel position of the country which had severely reduced the Company’s coal stocksrendered it necessary to reduce our beer output from February 17th by 33 1/3 %. The Company was recently given permission to use oil fuel and an order was immediately placed for the necessary equipment to convert the Company’s boilers to oil firing. Owing to the great demand for this equipment, and now the closing down of many works through lack of fuel, it may be some months before it can be installed. It is hoped, however, that the fuel situation will soon improve and that we shall be able to carry on, and the serious cut in production quickly restored.

June 1947: We have received a small consignment of the new beer bottlethe Company has adopted with the label sand-blasted in the glass. People that have seen them (including the makers) tell us the design of the label is most attractive and one of the best they have seen. These bottles are more expensive than the ordinary bottle, but some savings should be effected in not having to purchase paper labels, the elimination of labelling and easier washing. the label will always be in position and present a smarter appearance to the finished article. To distinguish the contents, distinctive crown corks will eventually be used bearing the name of the beer, but as these are not available at present, plain coloured ‘crowns’ are being used for the time being. Colours for the different beers are as follows: All Bright – Gold; Home Brewed – Blue; Stout – Brown; Guinness – Green; Worthington – Grey, and Bass – Red.

September 1947: 7,000 Bottles an hour: A description of the New Beer Bottling Plant by W.H. Painter. On Tuesday, 16th July, we commenced production on the new ‘Liquid’ bottling unit coincident with the introduction to the public of the new type bottle the Company has adapted. Although this first run maximum output was not the objective, results obtained were most satisfactory and the unit behaved splendidly in every way. The complete unit weighs a little over thirty-five tons and has a capacity of 500 dozen pints or 600 dozen half pints per hour. It was manufactured by the Liquid Carbonic Co., Ltd., of Peterborough, and comprises a Superkleen Model QH 123 Multistage High Pressure Bottle Cleaner, a 40 Head Balanced Counter Pressure Beer Filler, and an 8 Head Rotary Crowner. To assist those who have not seen the unit in production the mode of operation is as follows:- The empty bottles are placed by hand on a steel serrated plate and are then automatically fed into pockets twelve wide, which form part of an endless chain passing through and under the washer. The bottles are first rinsed with warm water, then pass through three separate soaking tanks each containing varying percentages of detergent solution, and each maintained at a thermostatically controlled temperature. The bottles pass from the third tank through a chamber where they receive four independent internal and external rinsings with hot detergent solution, afterwards being subjected to a deluge of plain warm water and two rinsing’s internally of plain hot water. Finally, the bottles receive three internal and external rinsings with cold soft water. During its ultimate stages through the washer the bottle is thoroughly drained and when automatically ejected the result is a perfectly brilliant, sterile bottle. On discharge from the washer the bottle is placed automatically on a moving chain conveyor whence it is conveyed to the Filling Machine. Here, by means of clever design, filling heights can be carefully controlled, and all chipped or cracked bottles rejected. A series of air operated safety ‘Gates’ preclude the possibility of damage to the machine or bottle at every stage. The bottles, after filling, are automatically discharged on to the infeed plate of the eight head Rotary Crown Corking machine discharging on to a fast-moving conveyor which carries them to the Accumulating Table from which they are placed into cases and carried by conveyor to the Full Beer Stores. The introduction of the new type of crown cork bottle with permanently enamelled label makes it possible to dispense with Stopper Tightening Machines, Labelling Machines, etc. This reduction in the number of machines to the bottling unit results not only in the lessening of running costs but also a considerable economy of space. Even more important, the moment the bottle is filled it is hermetically sealed with a hygienic closure, this conserving the quality and eliminating loss of gas in the beer. It is felt the adoption of this new bottle will have a considerable influence on our future sales, and advantageously displayed in our houses, act as a highly important advertising medium, particularly so when restrictions permit the coloured crowned crown corks being printed with the Company’s Trademark, etc. The article had a photograph of the original bottling plant installed when the new Bottling Stores was erected in 1938. This unit has done good service throughout the war and is still in daily operation. The new Unit is of similar design and layout but much larger and capable of double the output.

March 1948: As from January 1st, the Government has cut down supplies of brewing sugars, which means that brewings have had to be reduced again, consequently supplies to our houses have reluctantly been further curtailed. This is unfortunate, as every house is asking for more beer, not less, and no Stroud house appears to have sufficient supplies to open the full number of hours. It is gratifying to know that ‘Stroud Beers’ are so popular, but it is regretted that supplies are not sufficient to meet the demand.

March 1948: The Company had also arranged to equip the brewery boilers for burning oil fuel when the Government had to curtail coal supplies. Unfortunately, the firm who was give the contract owing to unforeseen difficulties, were unable to carry out the work in the time specified, and although the equipment has now arrived, it is not yet operating, as the Government has now stopped deliveries of fuel oil until additional stocks have been built up in the country. Fortunately, we have received sufficient coal to keep the fires burning.

June 1948: On April 7th a leakage of ammonia fumesin a part of the Beer Bottling Stores at Salmon’s Spring made it necessary to call in the assistance of the local fire brigade. The firemen, equipped with oxygen breathing apparatus, were able to enter the affected area and open the doors and windows. Once the rooms had been ventilated, the leakage was located by Mr Prowting, who shut off the valves and drained the system of ammonia. Unfortunately, before the arrival of the firemen, one of the employees, George Mitchell, was overcome by the fumes and was taken to Stroud Hospital, where he was treated and detained. We are glad to say that he has now recovered. One of the firemen also had an unpleasant experience, for he slipped when mounting the stairs and, in falling, wrenched the connecting tube from his mouth. He was overcome by the fumes and had to be taken to Stroud Hospital but was able to go home later.

June 1948: Mr A.D. Cook designed the new poster now appearing on the hoardings. The tankard should soon be recognised as the House Mark of the Stroud brewery, as it also appears on new Waiter trays and Ash trays recently received.

December 1948: The Cooler Room has been renovated and modernised and is an undoubted improvement.

March 1949: Stroud Brewery’s Contribution to the Improvement of Malting Barley: Since the Stroud Brewery Company was incorporated in 1888 the tradition of co-operating with the farming community had been maintained, and there has always been one or two members of the Board directly interested in agriculture, who have given valuable help and assistance in finding the most suitable types of malting barley to grow on the brashy soil of the Cotswolds. A notable example of the close co-operation between the Brewery and Agriculturalists was given in January 1935 when a large and representative company of farmers, at the invitation of the Directors, attended the Brewery for a friendly discussion on the subject of malting barley. Mr Ernst Armitage presided, supported by other Directors and the Company’s Head Brewer, Mr Walter Lionel Powell, who gave an informative and practical address on ‘barley cultivation and its after treatment’. Questions were asked and answered, and the visitors were afterwards entertained to luncheon by the Company and most of the guests took the opportunity of inspecting the maltings, brewery and other departments of the Company.

For many years prior to the Second World War, the Company continued to offer prizes purchased by them direct from growers within a radius of 5 miles of Tetbury, but instead of cups three monetary prizes were given. The barleys were judged by an independent person and competitors were invited to the Brewery to see the samples and discuss points of mutual interest arising out of that season’s crop. To further widen the interest and to encourage the growing of still better malting barley on the hilly ground of the Cotswolds, the Company is this year presenting a silver Challenge Cup to the Gloucestershire Rot, Fruit an Grain Society to be completed for annually. A souvenir will also be given to the winner as a permanent memento of his achievement.

June 1949: Reports were received of the excellent quality of the beer at Easter. our district representatives have been told that visitors to Gloucestershire speak very highly of Stroud ales now being sold at 1/- per pint.

December 1949: The Company are introducing a new brand of beer to be known as ‘Cotswold Ale’. This new beer will be sold in Public Bars at 1/4d per pint. A new bottled beer will also be on sale in our licensed houses as from the 6th December and will be known by the same name. This bottled beer will be of a slightly higher gravity and will be pasteurised. This will no doubt be a popular drink and will be available in public bars at 1/- per half-bottle.

December 1950: A new bottled beer known as Cotswold Ale was introduced for sale in our licensed houses on the 6th December 1949. It was realised that it would be a popular drink at a popular price, but sales in November, a poor month usually reached a very high level

September 1952: Our bottled ‘Cotswold Ale’ introduced in December 1949 has become extremely popular and is in great demand. A photograph reached us recently of a member of the Parachute Regiment drinking ‘Cotswold Ale’ in the Canal Zone. We have no Depot there – yet. They were bottles taken back by the troops when on leave.

December 1952: A sister to ‘Cotswold Ale’ is now on the market. this new product is known as Cotswold Stout. many demands have been made for a sweet stout, and there is no doubt that this drink will be a popular one. Cotswold Stout became available on the 1st December and will be on sale on all public bars at 1s.0d. per half bottle.

1953 (March): 12,000 Bottles per hour. Consequent upon the increase in demand for our Bottled Beers, it has become necessary to supplement the existing machinery at our Salmon’s Spring Beer Bottling department to cater for this trade. The Company has taken the long-term view that the popularity of our Bottled Beers is now firmly established and have accordingly arranged for the installation of a new bottling unit with a capacity of 1,000 dozens per hour. This unit will be accommodated in a completely new factory, and necessitates such additional new plant as boilers, water softeners, case conveyors, increased storage capacity in both the Conditioning Rooms and the Cold Store, etc. The complete unit in working order weighs something in the region of 100 tons, and automatically takes control of the bottle from the time it is placed on the washer feed to the point where it is discharged – filled, crowned, pasteurised, and labelled one and a half hours later on to a fast-moving case conveyor transporting the cases to the Full Beer Stores. Bottles are placed by hand in the magazine infeed of the Washer, whereby mechanical means they are fed in a single row into pockets each twenty bottles wide. Many these pockets form an endless chain which passes through and under the washer to recommence the sequence. The machine is divided into four compartments, each filled with a detergent solution and thermostatically controlled at a predetermined temperature. Each pocket passes through these tanks and the bottles are therefore thoroughly soaked before reaching the powerful jets which spray them inside and out with the detergent solution. After receiving this treatment they are again subject to powerful hot liquor and finally cold liquor rinsing before they are automatically discharged on to a fast moving bottle conveyor which takes them to the 50 Head liquid Filling Machine. It is interesting to note that the washer is equipped with several safety devices, this safeguarding both the machine and bottles it handles against breakage. The Crown safety device stops the machine in the case of a bottle with crown cork intact reaching the hot water rinse, together with a final automatic cut out, so that misplaced bottles on the discharge conveyor cause an immediate stop. The sterilised bottles are afterwards fed to the Filling Machine, which is also capable of infinite adjustment of speeds up to 1,000 dozs. per hour. Due to a system of filling control, chipped or cracked bottles are rejected, and filling heights are capable of very accurate adjustment. The crowner forms really an essential part of the filler, it’s duty being to apply the crown corks firmly as quickly after filling as possible. The crowned bottles now pass along a further conveyor belt to the infeed of the Pasteuriser. The pasteurising process takes one hour to complete, and at any one time during the working day contains as many as 1,000 dozens. It is essentially a constantly moving platform which carries the bottles through five different heating and/or cooling zones. The temperature of the beers is gradually increased to the critical pasteurising temperature where they are ‘held’ for approximately twenty minutes, afterwards being cooled to a point where they can be safely handled. The temperature of the heating and cooling zones are thermostatically controlled and a thermograph provides an accurate temperature throughout the working day. To complete the process, the bottles pass through a dividing head to one of two Labelling Machines before placing them in cases for transit to the Full Beer Stores. W.H.Painter.

Gloucester Pubs: Trumpet, Three Kings, Robin Hood, Crown Hotel, Llanthony Bridge, Worcester Arms, Dial Inn (St Marys Sq), Britannia (St Marys), Duke of York, Anchor (Sweetbriar Street)

1953 (June): ‘Congratulations are due to Michael Wearren for the design [of the Coronation Decorations] which has proved both artistic and practical, and to John Cook for the admirable way in which that design was interpreted and executed by him in the full scale finished scheme. The combination of their artistic work resulted in a tableau that will be long remembered by all who saw it, and it has provided for thousands of visitors from near and far, a vivid and colourful spectacle, whether viewed in daylight or by night. An appreciation too, is due to all others – mainly from our Building Staff – who co-operated by their labour and skill to achieve the final effect’. – K.B. Godsell, Lt. Col.

Jan 1957: At Stroud Brewery’s annual meeting, the chairman (Lt Col K.B. Godsell) reported a successful trading year with trading figures and dividends maintained. The net profit of £129,278 exceeds last year’s figure by £19,000.

February 1959: ‘A new plant has been installed at the Stroud Brewery’s factory at Salmon’s Spring capable of bottling 24,000 bottles of beer an hour. It will meet the increasing demand for bottled beer and is claimed to be the largest, fastest and most modern in the UK. ‘

1967: Cessation of brewing at the premises of the old Stroud Brewery Company which had been taken over by West Country Breweries. Fortunately, few jobs were lost since most transferred to new work at the Cheltenham Brewery depot.

1973 (October) ‘The disused brewery at the corner of Wallbridge and Rowcroft, Stroud, is to be demolished soon.’

Tippler April 1978 – ‘Heard on the Hop Vine … Whitbread Draught Bitter, brewed at Tiverton, uses an old Stroud Brewery recipe.

October 1978 – The Tippler No 10: ‘Whitbread Flowers have announced the closure of their three Gloucestershire distribution centres in a £1 million re-organisation scheme. A new depot which is still at the planning stage will be set up at Barnwood, Gloucester, and is expected to be operational in about 18 months’ time. The three depots affected are at Tuffley, which currently distributes Whites and Rawlings soft drinks which are produced by Whitbread, the Cheltenham depot next to the brewery which serves the tied trade and the Salmon Springs depot at Stroud. Salmon Springs was the site of the Stroud Brewery (sic) but now distributes to the free trade. It is to be disposed of in the rationalisation thus ending a long association that Stroud has with the brewing industry.

March 1985: the Stroud & Swindon Building Society acquired the site of the old Stroud Brewery for their new multi-million-pound HQ.

1989 (July) ‘Building work was started on the biggest-ever office development in Stroud. The Stroud and Swindon Building Society is investing £5.1 million in its headquarters complex on the old brewery site at the junction of Rowcroft and Merrywalks.’

Taste recollections:

‘I recall Stroud beers had a lasting flavour, stronger than Cheltenham’s ales, a hint of cloudiness, and an aroma that brought out the malt.’ Alan Watkins 23rd May 2000.

‘I checked with my dad, who worked in Stroud in the early 1950’s and grew up in Cambridge, Glos. He can remember these beers and says he thinks Stroud Beers were superior to Cheltenham’. Samantha Veale 23rd May 2000.